Some Thoughts on Piston Valves and Lubrication...

Aside from some occasional calls at the basement shop (the engine is still there...), my main occupation with the engine was as „armchair culprit“.

The Pearl engine, which features a piston valve, has been designed for outer admission. This layout is a complete mystery to me, because

1. the pressure load on the stuffing box is higher than in an engine with inner admission

2. when using the steam inlet connection recommended by the manufacturer (lower opening of the piston valve cylinder), the inlet path is almost blocked by the piston valve when it reaches the bottom position.

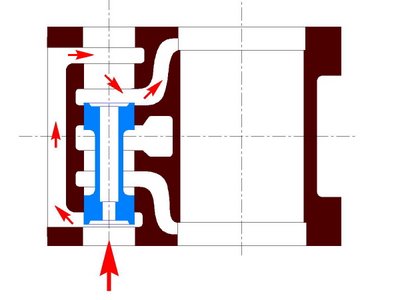

Longitudinal section of the cylinder, showing the original piston valve. Piston rod and stuffing box are on top. The piston nearly blocks the steam inlet path.

For these reasons, I am considering to re-design the engine for inner admission. The resulting piston valve is shorter, and does not block the steam exhaust.

Re-arrangement for inner steam admission. Piston valve featuring labyrinth sealing (see further down)

The cylinder lubrication issue keeps me busy. I am aware of the fact that a minimum of lubrication is absolutely necessary with some designs, especially when using cast iron or if the engine features slide valves. Considering the great deal of measures necessary to separate the oil when operating in the condensing mode, the idea of being able to do without it is very tempting. Would it be possible to run my engine without cylinder lubrication?

In this regard, I cannot count on the experience of other Pearl users. No information is available about cylinder lubrication - not even from the manufacturer -, to say nothing of the contact address of further customers. Two single-cylinder engines are presently being built in France, however in the cast iron execution. According to my information, just two twin cylinder engines have been sold to Europe. The second one (hello Hans...!) is being assembled in Sweden from a machined cast-iron set.

My engine features bronze cylinders and piston valves. Due to the design of the piston valve cylinder (annular grooves), no piston rings can be used for the piston valve. Sealing is then reached by means of a tight fit. At first glance, the material matching (bronze / bronze) is not very suitable. But because no friction should actually take place, this material matching is the ideal one with regard to thermal expansion: the fit remains constant at different operating temperatures.

Now to cylinder lubrication. The engine will be operated with saturated steam. Could a kind of labyrinth seal (narrow, 1-mm grooves as shown above) be a sufficient measure to achieve the necessary oil-free sealing?

The main piston is another story . The owner of SL „Felizitas“ (the engine of which is operated without cylinder lubrication) told me that they are testing plastic piston rings (of unknown material...) which do not last very long. Titanium was also mentioned (??), which has a far lower thermal-expansion coefficient than bronze.

What about proceeding according to the motto: „The proof of the pudding is in the eating“? Suggestions are welcome.

0 Comments:

Post a Comment

<< Home